The polymer industry stands as a cornerstone of modern manufacturing, playing a vital role in producing thousands of products, from simple packaging to complex automotive parts and medical devices. Given this scope, the international trade of polymeric materials (both exports and imports) is one of the most dynamic yet complex fields in global commerce.

Success in this market is not merely about finding a buyer or seller; it requires a deep understanding of technical specifications, logistics, financial instruments, and legal frameworks. In this article, we will explore the most critical factors that every trader in the polymer sector must carefully consider.

1. Precise Technical Knowledge and HS Code Classification

The first and most fundamental step in the polymer trade is knowing your product inside and out. The world of polymers is vast:

- Polymer Type: Are you dealing with Polyethylene (PE), Polypropylene (PP), PVC, Polystyrene (PS), or PET?

- Grade: Each of these polymers has dozens of different grades (e.g., injection, film, fiber, pipe grade) with distinct physical and chemical properties.

- HS Code Classification: Assigning the correct Harmonized System (HS) code is crucial. A minor mistake in this code can lead to incorrect customs duties, heavy fines, or even the seizure of goods at the destination port.

Key Takeaway: Always meticulously review the Technical Data Sheet (TDS) and the Certificate of Analysis (COA) of the product. This ensures the goods perfectly match the customer’s order (for exports) or your own requirements (for imports).

2. Understanding Market Dynamics and Price Volatility

The polymer market is highly dependent on the price of raw materials (feedstock) like crude oil and naphtha. This market is characterized by intense and rapid price volatility.

- Market Analysis: Continuously monitoring global prices (such as Platts indexes), regional supply and demand, and energy costs is essential for predicting price trends.

- Price Risk: In large-volume transactions, fixing prices in contracts or using financial risk management tools can prevent significant losses from sudden market fluctuations.

3. Specialized Logistics and Packaging

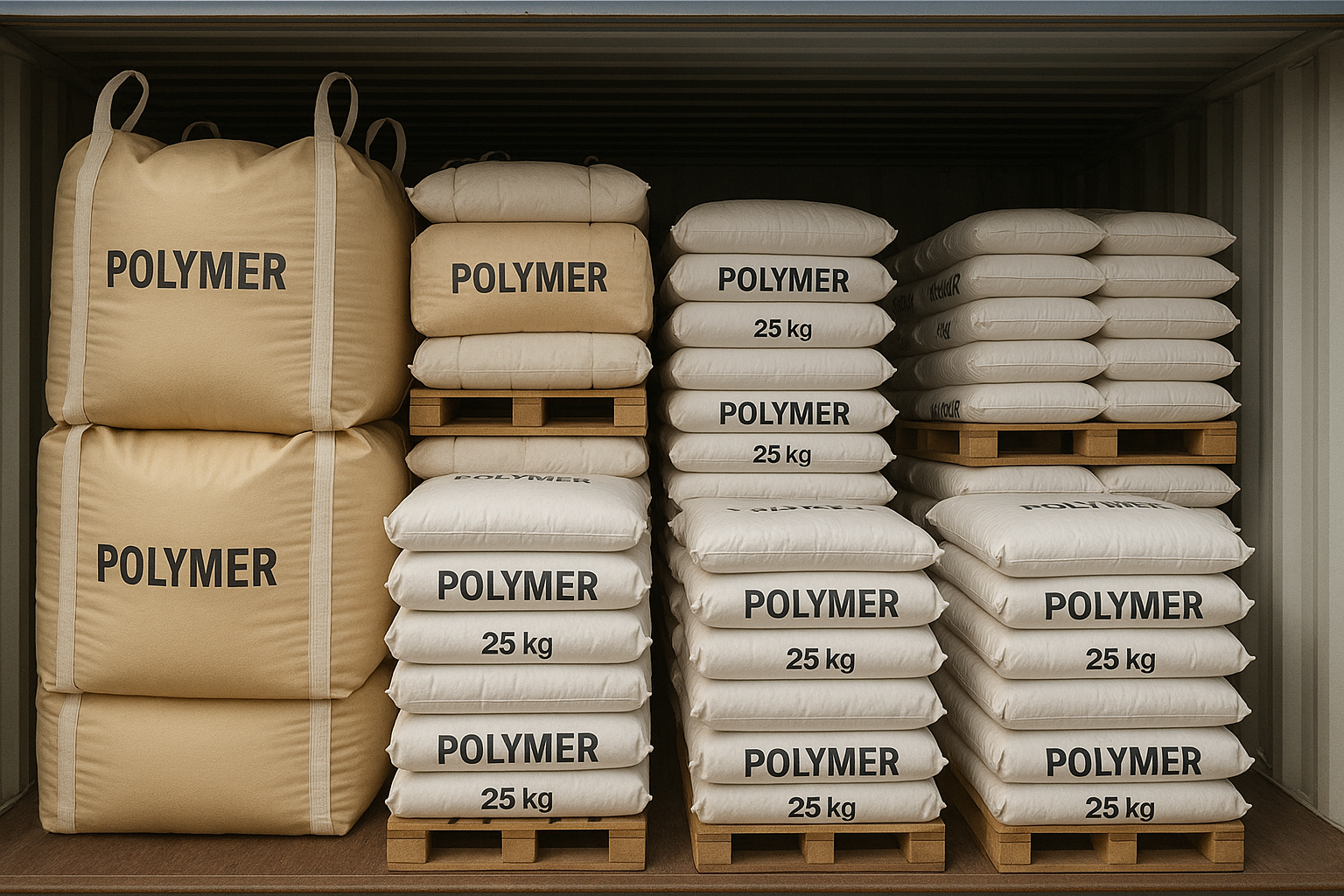

Transporting polymers, especially in bulk, presents its own unique set of challenges.

- Mode of Transport: The choice between bulk shipping in specialized vessels, using containers equipped with liner bags (to prevent contamination), or packing in 25kg bags and jumbo bags depends on the customer’s needs and economic feasibility.

- Quality Preservation: Polymers must be protected from moisture, contamination, and sometimes extreme temperatures. Inadequate packaging can render an entire shipment worthless.

- Freight Costs: Given the extreme volatility of sea freight rates in recent years, managing logistics costs has become a primary pillar of profitability.

4. Legal Regulations and Compliance

International polymer trade is subject to a complex set of regulations in both the origin and destination countries.

- Environmental Standards: Many countries, particularly in the European Union (under REACH regulations), impose strict restrictions on the import of polymers and their additives (such as heavy metals).

- Health Regulations: If the polymer is intended for medical use or food packaging (Food Grade), it must have the necessary health and safety certifications.

- Sanctions and Trade Restrictions: Verifying the status of any potential sanctions against the country of origin, destination, or companies involved in the deal is essential to avoid legal and financial complications.

5. Commercial Documents and Financial Processes

Accuracy in documentation is the master key to ensuring smooth customs clearance and timely payment.

- Key Documents: A set of documents including the Commercial Invoice, Packing List, Bill of Lading (B/L), Certificate of Origin (C/O), and Certificate of Inspection (COI) must be prepared with zero discrepancies.

- Payment Methods: Choosing the right payment method (such as Letter of Credit – LC, or Telegraphic Transfer – T/T) based on the level of trust with the counterparty and the transaction’s risk is vital. In high-value polymer deals, using an LC is common to guarantee payment.